Linkeo est un spécialiste dans la création de sites web et du référencement sur les moteurs de recherche, et du community management.

Linkeo traite pour ses clients le community management sur les réseaux sociaux ou la création de photos et de vidéos pour leur site internet. Il propose aussi des logiciels de gestion de ventes rattachés aux boutiques en ligne.

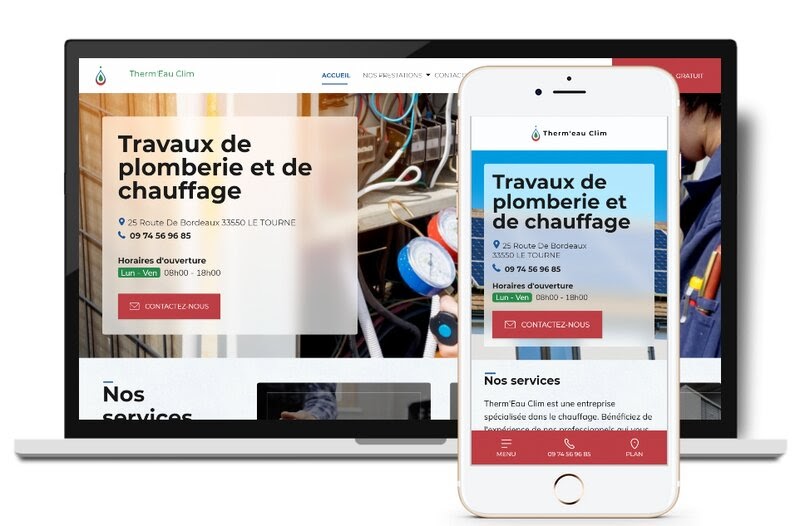

Création de site internet de Linkeo

Linkeo se charge de la création de site internet, que ce soit à l’usage professionnel ou personnel. En plus de la création, il propose la modification et l’optimisation de sites déjà existants.

Les sites web créés sont responsifs et s’adaptent aux écrans mobiles, dont les sites de boutiques en ligne sont également pris en charge :

- Sites catalogue : mise en ligne des produits ;

- Sites e-commerce : site de vente en ligne 24h/24, avec un catalogue indiquant la disponibilité des produits ;

- Sites vitrine et corporate : présentation de l’entreprise, de ses activités et de ses prestations ou produits.

Une offre spécifique est également proposée pour les agents immobiliers. Une fois le site créé, Linkeo se charge de son référencement.

Référencement de site de Linkeo

Le référencement d’un site lui donne de la visibilité sur internet, notamment en le plaçant au top des résultats de recherche. Le Search Engine Marketing regroupe les types de référencement et de publicité donnant cette visibilité :

- Search Engine Optimization (SEO) : référencement naturel, amélioration du contenu et structure du site pour qu’il soit priorisé par les moteurs de recherche ;

- Search Engine Advertising (SEA) : référencement payant, amélioration de la position du site dans les résultats de recherche ;

- Social Media Optimization (SMO) : l’attraction de visiteurs sur le site à travers les publications sur les réseaux sociaux ;

- Social Media Advertising (SMA) : les campagnes de publicité payantes sur les réseaux sociaux.

Linkeo s’occupe de l’optimisation SEO du site et assure un bon maillage des liens :

- Internes : pour faciliter la navigation des utilisateurs au sein d’un site web ;

- Externes : pour apporter de la visibilité à une audience afin de les rediriger sur le site web client.

Par la suite, la compagnie va lancer et gérer les campagnes de publicité payantes, en se chargeant de la rédaction d’annonces, du budget et en donnant des rapports de performance au client.

Solutions métiers de Linkeo

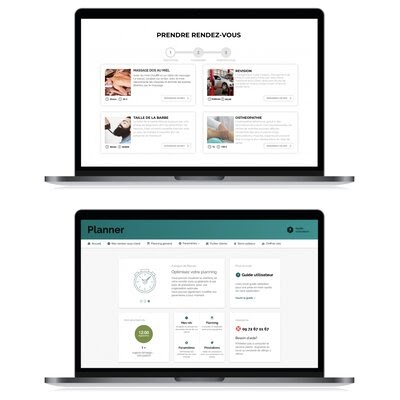

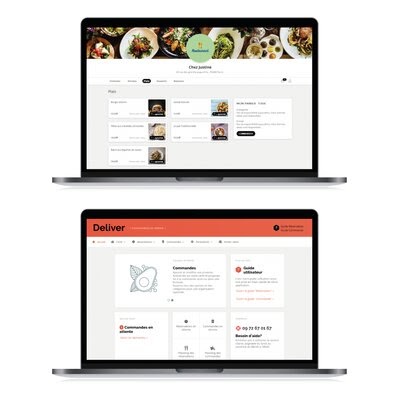

Linkeo propose 2 logiciels en ligne pour faciliter les ventes de produits et la gestion de l’agenda pour les services :

- Deliver ;

- Planner.

Deliver permet aux clients de visionner une boutique en ligne, et passer leurs commandes selon la disponibilité du stock des articles. Une fois la commande passée, ils n’ont plus qu’à passer récupérer la commande, ou se la faire livrer directement. Les ventes sont multipliées tout en évitant les commandes de produits indisponibles.

Planner sert de gestionnaire de planning pour tous les rendez-vous avec les clients. Il permet aux prestataires de services de renseigner leur disponibilité à leurs clients. Ce logiciel propose aussi le regroupement des clients pour les prestations collectives, et donc de combiner des rendez-vous. Les paiements en ligne avec Stripe sont également disponibles sur chaque logiciel.

Planner

Deliver

Community Management de Linkeo

L’équipe de Linkeo se charge de la création de contenu pour les publications sur les réseaux sociaux, dont :

- Facebook ;

- Twitter ;

- Instagram ;

- LinkedIn.

La compagnie ajoute également 2 sections au site :

- Avis client : confiance des visiteurs quant à la fiabilité et la qualité des produits et prestations ;

- Newsletter : confirme l’activité du site, en plus d’améliorer sa crédibilité en donnant des informations utiles aux internautes.

Photos et Vidéos de Linkeo

Les photos et vidéos illustrant le site donnent une image sérieuse de l’entreprise et incitent les clients à passer à l’acte d’achat plus rapidement. Pour orner le site, Linkeo propose la prise et la création des éléments suivants :

- Des photos professionnelles : en envoyant un photographe pour aider le client à prendre ses photos ;

- Des visites virtuelles 360° : à travers lesquelles le client peut faire connaissance avec les lieux ;

- Des présentations animées : à afficher sur le site web ;

- Des présentations vidéos : expliquant les produits ou services et démontrant le sérieux de l’entreprise.

À propos de Linkeo

Linkeo est présent dans le domaine de l’internet depuis l’année 2000. Depuis, cette agence digitale n’a cessé de s’améliorer en proposant des création de site web, en optimisation leur référencement, tout en s’adaptant aux algorithmes des moteurs de recherche. L’agence Linkeo dispose à présent de plus de 20 agences à travers le monde, dont la France, le Canada, Les États-Unis et l’Australie.

Adresse de Linkeo

23 rue des Grands Augustins

75006

Paris

Tél : +33 8 00 94 98 48

E-mail : [email protected]

Horaires d’ouverture de Linkeo

| Jour | Horaires |

|---|---|

| Lundi | 08:30 – 18:00 |

| Mardi | 08:30 – 18:00 |

| Mercredi | 08:30 – 18:00 |

| Jeudi | 08:30 – 18:00 |

| Vendredi | 08:30 – 18:00 |

| Samedi | Fermé |

| Dimanche | Fermé |